Gyeongnam Changwon Smart Green Industrial Complex - Local Governments

Gyeongnam Changwon Smart Green Industrial Complex

Gyeongnam Changwon National Industrial Complex was selected as a smart green industrial complex to create a world-class high-tech machinery industrial complex under the heavy chemical industry promotion policy. Major industries represented at the complex are machinery (59.2%), electrical and electronics (19.5%), and transportation equipment (9.6%).

Location Overview

- Location :Agricultural Technology Center site in Changwon (71, Changi-daero, Uichang-gu, Changwon-si)

- Total Area :Around 25,302,000 ㎡

- Project Period :’19.10 - current

- Total production amount :KRW 39,196 billion

- Total amount of export :USD 9,597 million

- Number of tenant companies :2,754

- Number of employees :124,950

Key Highlights

- (Establishment of test line) Establishment of 3 modular test lines (processing, assembly, and inspection) based on digital twin

- (Professional manpower training) Plan to nurture talent in smart manufacturing in cooperation with KPC and universities in Gyeongnam and develop different levels and stages of educational programs, etc.

- (Development of evaluation system and validation) Development of evaluation and test system to predict the durability of smart manufacturing core parts, modules, and equipment, and to verify the failure rate

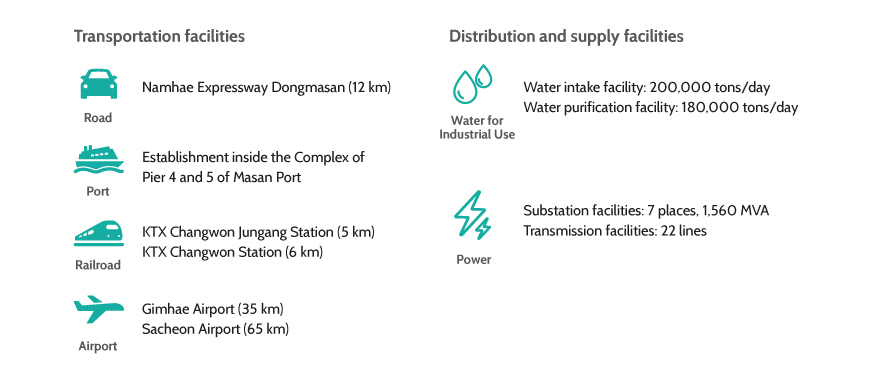

Location Conditions

Plans for the supply and expansion of smart factory

- Targets : Domestically registered manufacturing corporations

- Recruitment period :January 22, 2021 - June 30, 2021

- Department : Korea Smart Manufacturing Office

- Details

You can check the table by moving it from side to side.(Touch to close the information window and use it.)Project Title Support Application Type Government Subsidy

(KRW, per company, max)Establishment and Advancement of Smart Factory Provision of automation equipment, controllers, sensors, etc., necessary for producing a smart factory solution using advanced technologies such as IoT, 5G, big data, AR, VR, AI, and cloud for the improvement of product design and production process Basic 0.7 billion Advancement 1 200 million Advancement 2 400 million

Major Development Plans

You can check the table by moving it from side to side.

(Touch to close the information window and use it.)

| Expansion of Smart Convenience Facilities (integrated control) |

Operate a system using IoT technology, intelligent CCTV, and data from related organizations to manage dangerous goods, environmental pollution, and traffic in the complex *Install IoT environment sensor system (actual measurement information) + construction of intelligent CCTV (video information) + connection of public data (weather, environment, terrain information, etc.) → Real-time monitoring and increased risk prediction accuracy of the industrial complex |

|---|---|

| Expansion of Smart Convenience Facilities (logistics platform) |

Reduce logistics costs and utilization of idle warehouses in the industrial complex by applying ICT and AI technology to the obsolete joint logistics center *Provide devices such as sensors for joint logistics companies and logistics providers (transport, storage, etc.), data collection, and intelligent control of supply and demand in logistics |

| Process Innovation Simulation Center | Reinforce smart manufacturing innovation capabilities of SMEs through virtual design support for the entire process from product development to manufacturing to performance verification *Companies do not have to purchase costly software or leave the work to another company. The simulation provided by the center allows companies to reduce costs and time spent on product development. |

| Standard Manufacturing Innovation Process Module | Verify manufacturing technology and corporate support through the establishment of a modular production system for the application of smart manufacturing technologies such as digital twin |

| Professional Manpower Training in Smart Manufacturing | Develop undergraduate and graduate programs (employees, etc.) in smart manufacturing, design curriculum focused on problem-solving in the industry, spur industry-academia cooperation to nurture talent, and technical support |

| Establishment of Energy Self-Sufficient Infrastructure | Expand ESS and renewable energy power plants such as fuel cell plant and photovoltaic plant in the industrial complex, and demonstrate energy transaction networks based on electric vehicle power generation |